2025-05-12

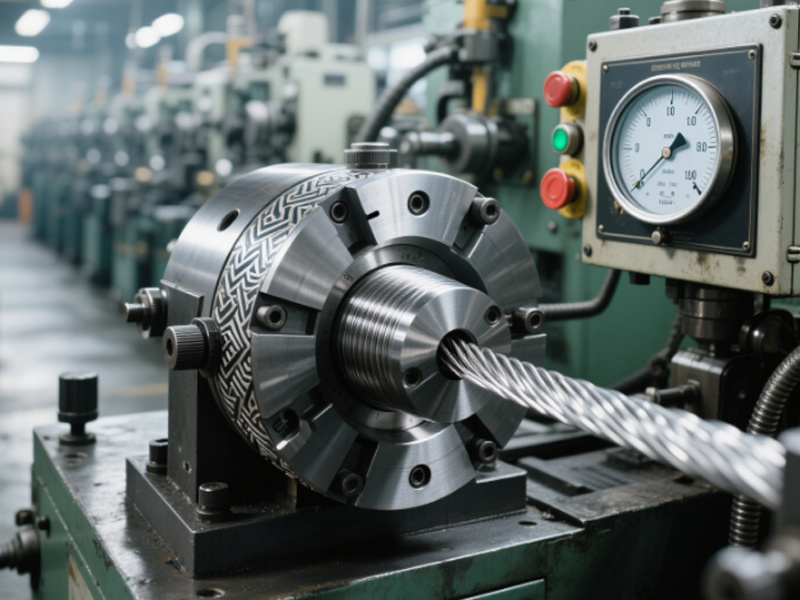

Irregular conductor cable mold mold characteristics

High-precision die design: The die mold is composed of a circular inlet section, a shaped inlet section, a deformation section, a sizing section, and an outlet section. The length ratio of each section is precise (e.g., circular inlet section 0.2L, shaped inlet section 0.2L, deformation section 0.3L, sizing section 0.1L, outlet section 0.2L), ensuring the continuity of the conductor twisting and pressing and deformation process and avoiding stress concentration caused by abrupt changes in the die shape.

2025-05-12

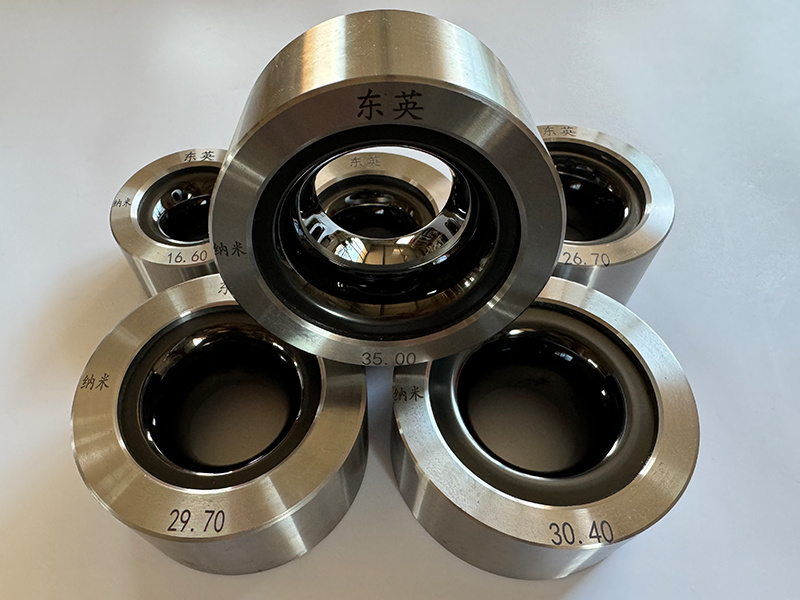

Preparation process of nano-diamond coated mold

Hot-wire CVD deposition method:

The excitation source (hot wire) is passed through the mold bore and placed at the axial position. By controlling parameters such as hot wire temperature, gas flow rate, and reaction time, uniform deposition of the nanodiamond coating is achieved. For example, in the nucleation stage, the hot wire reaction pressure is adjusted to 4.0~6.0 kPa, a mixture of hydrogen and methane gas is input, the flow rate is 1800~2300 ml/min, the methane volume fraction is 2~4%, and the reaction time is 40~80 min; in the growth stage, the reaction pressure is adjusted to 2.5~3.5 kPa, the mixed gas flow rate and methane volume fraction are adjusted accordingly, and the reaction time is 300~420 min.

2025-05-12

Technical characteristics of nano-diamond coated mold technology

Super Hard and Wear-Resistant:

Nano-diamond coating hardness reaches over 5000HV, more than 3 times that of traditional hard alloy molds, wear resistance is improved by more than 10 times, significantly extending the mold life.

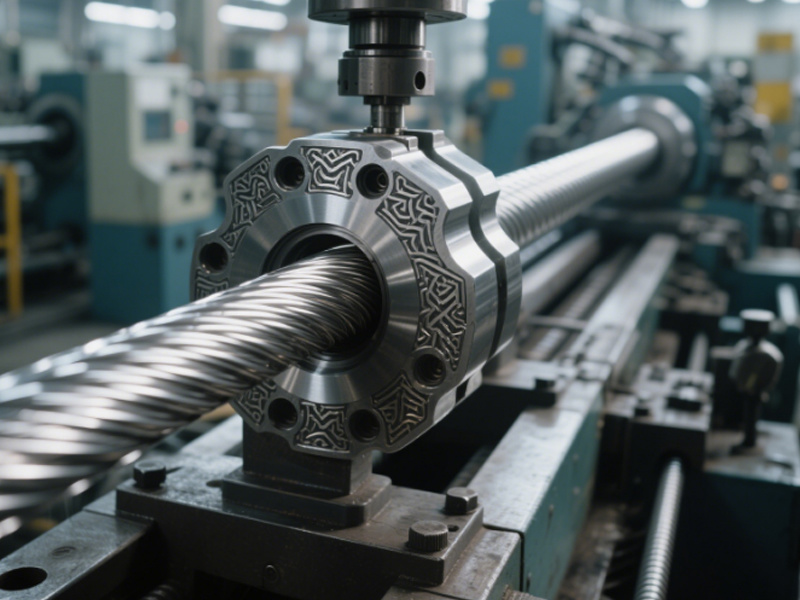

Key Application Areas of Special Shaped Wire Drawing Dies

Electronics and Electrical Industry

Used in the manufacturing of stainless steel strips (thickness 0.05-0.2mm) for smartphone frames and tin-plated copper stranded wires (complex cross-sectional shapes) for high-voltage wiring harnesses in new energy vehicles.

12

2025/05

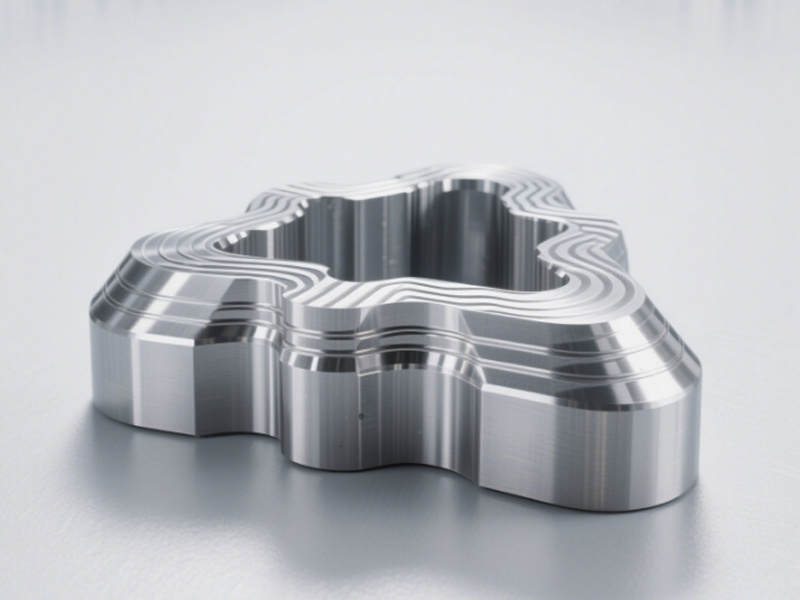

Core characteristics and classification of special-shaped wire drawing dies

Hard alloy: represented by tungsten cobalt alloy, hardness reaches above HRA90, wear resistance is 3-5 times higher than tool steel, suitable for high-strength metal processing.

12

2025/05