Dongying Mould Co., Ltd. is located in Tangzhuang Village, Beishicao Development Zone, Hejian City, Hebei Province. After more than 30 years of development, Dongying Company has established a complete production system covering wire drawing die core production, die pressing, laser processing, nano CVD coating, slow wire cutting processing, metal heat treatment, grinding, polishing, inspection, etc. Specializing in the production of copper wire drawing, aluminum wire, cable twisting tools, special-shaped conductor cable molds, smooth aluminum welding molds, shaping molds, tram contact wire molds, cable extrusion molds, BTTZ rigid fire-resistant cable molds (upper fixed sleeve, lower fixed sleeve, positioning block, multi-hole drawing molds, welding tools) and other materials made of hard alloy, poly diamond, nano CVD coating and die steel All kinds of tungsten steel and diamond wear-resistant parts.

15 years of production & experience

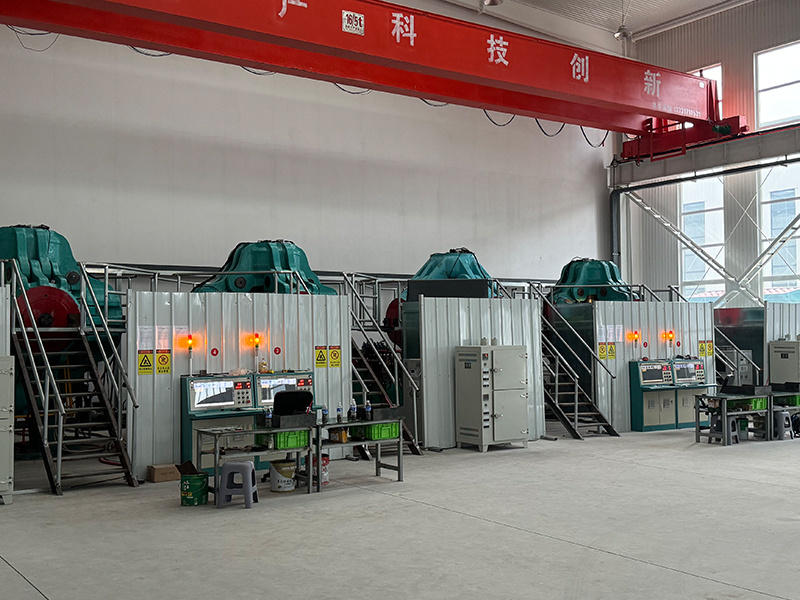

Production equipment

Partner

Cobalt based wire drawing die core (high crystal, CD)

Dongying Mold Company is committed to the research and production of high-quality superhard materials. Main production: High crystal, CD drawing die cores, slow wire cutting with 100% conductivity, no sand holes, no dry cracking phenomenon, and providing lining and laser perforation services. It is the only manufacturer in China that produces die cores and molds in one go.

Our company is one of the earliest manufacturers in China to use chemical vapor deposition method to grow diamonds in the inner holes of hard alloy molds, which is equivalent to coating the hard alloy molds with a layer of hardness similar to natural diamonds.

Special shaped conductor cable mold(copper special-shaped)

This product is installed on a regular mailbox or water tank wire drawing machine or a linear wire drawing machine, and is directly drawn into trapezoidal wire or SZ type wire (tile type), which is tightly pressed and twisted into a circular cable through a frame twisting machine or a fork twisting machine.

Round hole polycrystalline (high crystal, CD)copper wire, aluminum wire mold

The material of the mold core is divided into six types: polycrystalline diamond, highcrystalline diamond,CD diamond, nano diamond CVD coating, mold steel, and hard alloy.

Irregular diamond wire drawing mold

The special-shaped diamond wire drawing die uses CD conductive diamond as the core, ensuring quality. It is cut using the international top slow wire cutting machine, with an accuracy of ± 0.002m. The slow wire cutting machine is produced by Swiss company Shamir and Japanese company Shadick, ensuring accuracy.

The mold material is selected from 38 chromium molybdenum aluminum, 40 chromium, chromium 12, etc., and undergoes vacuum heat treatment process through CNC machining center forming, followed by grinding and polishing.

This product is installed on a regular mailbox or water tank wire drawing machine or a linear wire drawing machine, and is directly drawn into trapezoidal wire or SZ type wire (tile type), which is tightly pressed and twisted into a circular cable through a frame twisting machine or a fork twisting machine.

Real scene

Specializing in the production of hard alloy, polycrystalline diamond, and nano-CVD layers Molds made of die steel for copper wire drawing, aluminum wire drawing, cable twisting molds, special-shaped conductor cable molds, smooth aluminum welding molds, integral molds, tram contact wire molds, cable extrusion molds, BTTZ rigid fire-resistant cable molds (upper fixed sleeves, lower fixed sleeves, positioning blocks, multi-hole drawing molds, welding molds) and various tungsten steel and diamond wear-resistant parts.

Advantages of Dongying

Dongying Company has already established a complete production system covering wire drawing die core production, die pressing, laser processing, nano CVD coating, slow wire cutting processing, metal heat treatment, grinding, polishing, inspection, etc

Design ability

According to the product requirements of customers, we can apply advanced CAD/CAM technology to carry out precise mold design, ensuring that the mold structure is reasonable and the performance is reliable, and can efficiently produce products that meet quality requirements.

Manufacturing process

During the mold manufacturing process, mold manufacturers have mastered a variety of advanced processing techniques, such as numerical control processing, electrical discharge machining, wire cutting processing, etc

Technology research and development

To meet the constantly changing market demands and customer requirements, mold manufacturers will invest a large amount of resources in technological research and development

Full-process service

From the initial design of the product to the manufacturing, debugging and maintenance of the mold, the mold manufacturer can provide customers with full-process services

Blog

We are committed to the production and sale of high-quality wire drawing grinding tools

Understanding Tungsten Carbide Wear Parts: Enhancing Durability in Manufacturing

Tungsten carbide is a highly durable material known for its exceptional hardness and wear resistance. In the realm of manufacturing and machining, tungsten carbide wear parts are essential components that enhance the performance and longevity of various tools and equipment. These parts are particularly effective in high-impact and abrasive environments, where traditional materials may quickly degr

Know MoreCustom Solutions: Tailoring Special-Shaped Cable Molds for Unique Requirements

Introduction to Custom Solutions in Cable Mold Manufacturing The manufacturing industry is increasingly leaning towards **custom solutions** to meet specific operational needs. Among these, **special-shaped cable molds** have gained prominence due to their unique applications across various sectors. This article delves into the importance of tailoring cable molds, the manufacturing process involve

Know MoreUnderstanding Cable Extrusion Dies: Essential Insights for the Manufacturing Industry

Cable extrusion dies are pivotal components in the manufacturing of various types of cables, including electrical, telecommunications, and optical fiber cables. These dies are designed to shape raw materials into specific profiles during the extrusion process. Understanding the intricacies of cable extrusion dies is essential for manufacturers looking to enhance their production capabilities and i

Know MoreYour One Stop, One Solution!

Consulting customer service Communication Details

Determine the scheme Product quotation

Product proofing Determine the sample

Order Payment Determine the delivery date

Mass production on-time delivery

After-sales service After-sales evaluation

Do you have questions?

For a fast response, fill in the form and our team will get back to you shortly.