- Product Detail

-

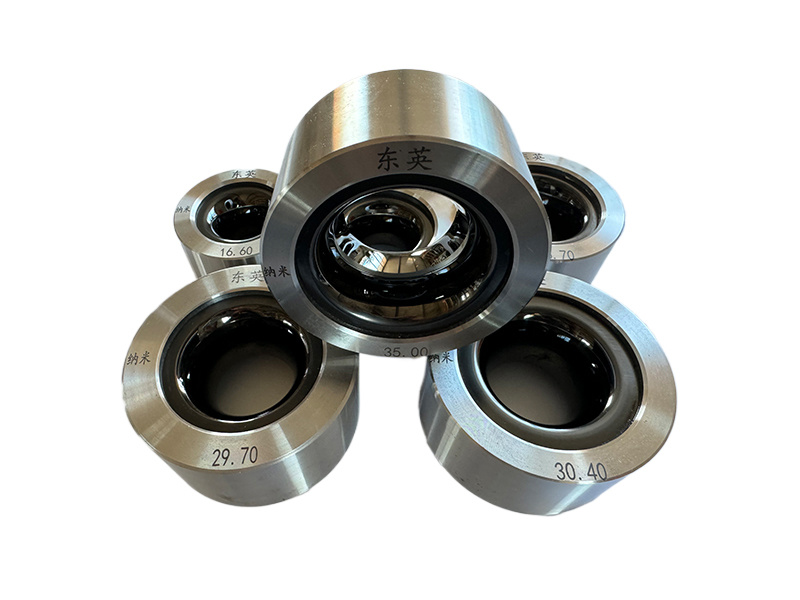

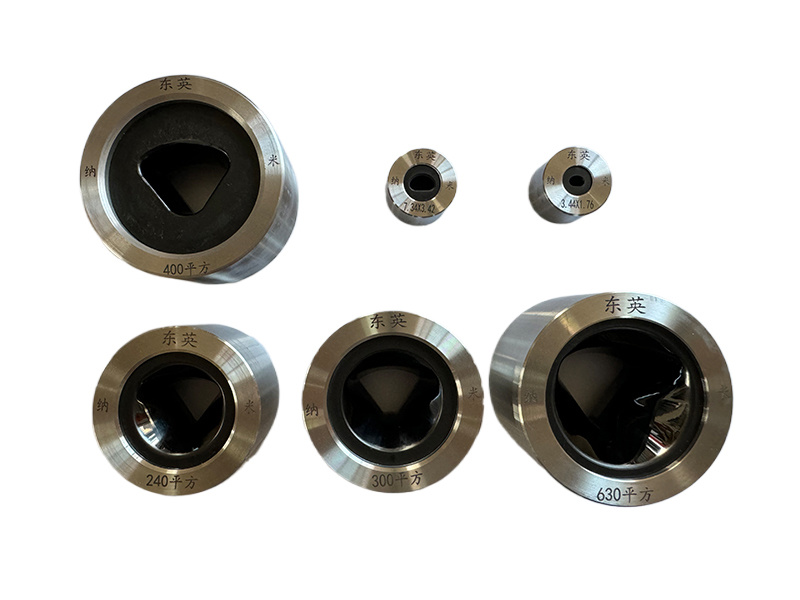

The special-shaped diamond wire drawing die uses CD conductive diamond as the core, ensuring quality. It is cut using the international top slow wire cutting machine, with an accuracy of ± 0.002m. The slow wire cutting machine is produced by Swiss company Shamir and Japanese company Shadick, ensuring accuracy.

Irregular diamond wire drawing molds include triangular, square, rectangular, hexagonal, circular, ladder shaped, bow shaped, tile shaped, and other irregular graphic molds, used in industries such as hardware, instruments, cables, and electric wires.

Product parameters

Number Tangential diameter Mold core size tolerance Mold sleeve size CDYX-0402 0.3~0.8 4×2 ±0.003 28×13 CDYX-5030 0.81~1.50 5×3 ±0.003 28×13 CDYX-6040 1.51~1.80 6×4 ±0.003 30×14 CDYX-8040 1.81~2.00 8×4 ±0.003 32×16 CDYX-9853 2.01~2.25 9×5 ±0.003 40×26 CDYX-1060 2.26~2.50 10×6 ±0.003 40×26 CDYX-1260 2.51~2.75 12×6 ±0.003 40×26 CDYX-1380 2.76~3.50 13×8 ±0.003 40×27 CDYX-1410 3.51~4.50 14×10 ±0.003 40×28 CDYX-1610 4.51~5.00 16×10 ±0.003 40×28 CDYX-1810 5.01~6.00 18×10 ±0.003 45×28 CDYX-2012 6.01~8.00 20×12 ±0.003 45×30 CDYX-2214 8.01~10.00 22×14 ±0.003 55×35 CDYX-2516 10.01~13.00 25×16 ±0.003 60×38 CDYX-3020 13.01~16.00 30×20 ±0.003 70×42 CDYX-4025 16.01~20.00 40×25 ±0.003 80×45

Company Profile

Dongying Mould Co., Ltd. is located in Tangzhuang Village, Beishicao Development Zone, Hejian City, Hebei Province. After more than 30 years of development, Dongying Company has established a complete production system covering wire drawing die core production, die pressing, laser processing, nano CVD coating, slow wire cutting processing, metal heat treatment, grinding, polishing, inspection, etc. Specializing in the production of copper wire drawing, aluminum wire, cable twisting tools, special-shaped conductor cable molds, smooth aluminum welding molds, shaping molds, tram contact wire molds, cable extrusion molds, BTTZ rigid fire-resistant cable molds (upper fixed sleeve, lower fixed sleeve, positioning block, multi-hole drawing molds, welding tools) and other materials made of hard alloy, poly diamond, nano CVD coating and die steel All kinds of tungsten steel and diamond wear-resistant parts.

FAQ

Can you accept small quantities?

Yes, accept small quantity, fast delivery

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

What is the minimum order quantity?

It depends on the product.

Previous:

Irregular diamond wire drawing mold

If you need customized delivery products, Contact US !

Products Category

Tag list

Releated Product

Enquiry

Thank you for visiting the official website, if you have any suggestions or cooperation intention, please contact us through the following ways, we will reply as soon as possible, thank you!